Automotive Logistics: The Backbone of Vehicle Manufacturing and Distribution

What’s automotive logistics?

Automotive logistics encompass the complete process of manage the flow of parts, components, and finish vehicles throughout the automotive supply chain. This specialized field handle everything from raw material source to the delivery of complete vehicles to dealerships and end customers. It represents a critical function that enable automotive manufacturers to build vehicles expeditiously and distribute them globally.

Source: unicornlogistics.com

The automotive industry operate one of the near complex supply chains in the world, with thousands of parts come from hundreds of suppliers across multiple countries. Effective automotive logistics ensure these components arrive at assembly plants at incisively the right time, in the right quantity, and in perfect condition.

Key components of automotive logistics

Inbound logistics

Inbound logistics cover the movement of parts and components from suppliers to manufacturing facilities. This includes:

- Exactly in time (jJIT)delivery a system where parts arrive at assembly plants incisively when need, reduce inventory costs and warehouse space requirements.

- Milk runs optimized collection routes where trucks pick up components from multiple suppliers in a single journey.

- Sequence centers facilities that will organize parts in the exact order they’ll be will need on the assembly line.

- Cross docking a practice where products from incoming shipments are instantly ttransferredto outbound vehicles with minimal storage time.

Production logistics

This involves the movement of parts within manufacturing facilities, include:

- Line side delivery ensure components reach assembly line stations at the right time.

- Kitting ppre-assemblinggroups of parts that will be will iinstallunitedly.

- Internal material handling use automate guide vehicles ((gages)conveyor systems, and forklifts to move materials expeditiously within plants.

Outbound logistics

Outbound logistics manage the distribution of finished vehicles from factories to dealers and customers:

- Vehicle transportation use specialized car carriers ((rucks, trains, ships ))o move finished vehicles.

- Vehicle processing centers (vPCs)) facilities that prepare vehicles for final delivery by add market specific accessories, conduct quality checks, and cleaning.

- Dealer delivery coordinate the final transportation to dealerships base on inventory needs.

Spare parts logistics

This branch handle the distribution of replacement parts for vehicle maintenance and repairs:

- Parts distribution centers regional warehouses that stock and distribute spare parts.

- Dealer parts supply systems to replenish dealership parts inventories.

- Express delivery expedite shipping options for desperately need parts.

Transportation modes in automotive logistics

Road transportation

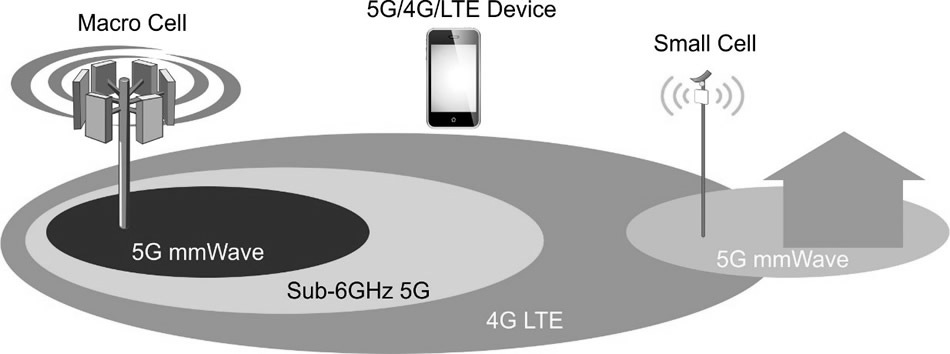

Trucks remain the virtually flexible option for automotive logistics, handle both parts delivery and finished vehicle transport. Specialized car carrier trucks can typically transport 8 10 vehicles at east. For parts, various truck types from vans to semi trailers are employ base on volume and weight requirements.

Rail transportation

Trains offer cost-effective transportation for long distances, particularly for finished vehicles. A single auto rack train can carry hundreds of vehicles, make it importantly more efficient than road transport for long hauls. Rail is besides progressively use for parts transportation in containerized shipments.

Maritime shipping

Ocean transport play a crucial role in global automotive logistics. Specialized vessels call roll on / roll off (rRory)ships can carry thousands of vehicles across oceans. These vessels feature multiple decks with ramps that allow vehicles to be drive on and forth expeditiously. For parts, container ships transport components in standardized shipping containers.

Air freight

While expensive, air transportation provide the fastest delivery option for critical components. Manufacturers use air freight during supply disruptions or for high value, lightweight components. It serves as a crucial backup when production schedules arethreatenedn by parts shortages.

Challenges in automotive logistics

Supply chain complexity

Modern vehicles contain 20,000 30,000 parts source from a global network of suppliers. Manage this complexity require sophisticated planning systems and coordination across multiple tiers of suppliers. The challenge grow with each new vehicle model and technology introduction.

Inventory management

Balance inventory levels present a constant challenge. Excessively much inventory ties up capital and require storage space, while excessively little risks production stoppages. Automotive logistics professionals must maintain optimal inventory levels across thousands of parts with vary demand patterns.

Transportation disruptions

Weather events, port congestion, labor strikes, and other disruptions can badly impact automotive supply chains. The industry’s reliance on exactly in time delivery make it peculiarly vulnerable to transportation delays. Develop contingency plans and alternative routing options is essential.

Environmental concerns

The automotive industry face increase pressure to reduce the environmental impact of logistics operations. This includes reduce carbon emissions from transportation, minimize packaging waste, and implement sustainable practices throughout the supply chain.

Source: ascentlogistics. Ae

Technological innovations in automotive logistics

Digital supply chain solutions

Advanced software platforms directly provide end to end visibility across automotive supply chains. These systems track parts and vehicles in real time, predict potential disruptions, and suggest mitigation strategies. Cloud base platforms enable collaboration between manufacturers, suppliers, and logistics providers.

Internet of things (iIOT)

Connected sensors on parts containers, vehicles, and transportation assets provide real time location and condition monitoring. These IOT devices track temperature, humidity, shock, and other factors that could affect quality. The data help optimize routes, prevent damage, and ensure timely delivery.

Artificial intelligence and machine learning

Ai algorithms analyze vast amounts of supply chain data to identify patterns and make predictions. These tools help optimize inventory levels, forecast transportation needs, and detect potential disruptions before they occur. Machine learning unendingly improve these predictions as more data become available.

Autonomous vehicles and robotics

Within warehouses and factories, autonomous guide vehicles (aages)and robots progressively handle material movement. Outside facilities, the industry is exexploredutonomous trucks and ships for parts and vehicle transportation. These technologies promise to increase efficiency and reduce labor costs.

Future trends in automotive logistics

Electric vehicle supply chains

The shift toward electric vehicles is transformed automotive logistics. Battery supply chains require different raw materials and components than traditional powertrains. The heavy weight oEVev batteries too impact transportation methods and costs. Logistics networks aradaptedpt to these new requirements while maintain support for conventional vehicles during the transition period.

Circular supply chains

Sustainability initiatives are drive the development of circular supply chains that recover and reuse materials. This includes reverse logistics for battery recycling, parts remanufacture, and vehicle end of life processing. These circular flows require new logistics processes and infrastructure.

Localized production

Geopolitical tensions, trade barriers, and supply chain vulnerabilities are encouraged more localize production. Manufacturers areestablishedh regional supply ecosystems to reduce logistics costs and risks. This trerequiresire reconfigure logistics networks to support more distribute manufacturing.

Direct to consumer delivery

Traditional vehicle distribution through dealer networks is being challenge by direct to consumer models. Some manufacturers directly offer home delivery options, bypass dealerships exclusively. This shift requires new last mile logistics capabilities and customer face delivery services.

The business impact of effective automotive logistics

Cost efficiency

Logistics typically represent 10 15 % of a vehicle’s total cost. Optimize these operations can importantly improve profitability. Efficient logistics reduce transportation expenses, inventory carry costs, and warehouse view graph. These savings can either increase margins or enable more competitive pricing.

Production continuity

Reliable logistics ensure manufacturing operations run swimmingly without interruptions. A single miss component can halt an entire production line, cost thousands of dollars per minute in lose productivity. Advantageously manage logistics prevent these costly disruptions.

Customer satisfaction

Timely vehicle delivery and parts availability instantly impact customer experience. Efficient outbound logistics ensure dealers maintain appropriate inventory levels to meet customer demand. For service parts, quick delivery keep customer vehicles on the road with minimal downtime.

Competitive advantage

Companies with superior logistics capabilities can respond more rapidly to market changes and customer preferences. They can introduce new models fasting, adjust production volumes more expeditiously, and recover more rapidly from disruptions. This agility provides a significant competitive edge in the speedily evolve automotive market.

Conclusion

Automotive logistics represent a sophisticated ecosystem that enable the global automotive industry to function. From the smallest fastener to complete vehicles, these specialize supply chains ensure that the right materials reach the right locations at exactly the right time. As the industry undergoes transformative changes with electrification, digitalization, and new business models, automotive logistics continue to evolve to meet these challenges.

The complexity of automotive logistics reflects the industry itservese — technically advanced, globally integrate, and invariably innovate. For automotive manufacturers and suppliers, master these logistics processes isn’t exactly an operational necessity; it’s a strategic imperative that forthwith impact business success. As vehicles become more technologically sophisticated and markets more demanding, the importance of efficient, resilient automotive logistics will merely will continue to grow.

MORE FROM feelmydeal.com