Automotive Primary Wire: Complete Guide to Wire Gauge Selection and Electrical Systems

Understand automotive primary wire

Automotive primary wire serve as the backbone of every vehicle’s electrical system, carry power from the battery to various components throughout the car. This specialized wiring differ importantly from household electrical wire, design specifically to withstand the harsh conditions find in automotive environments.

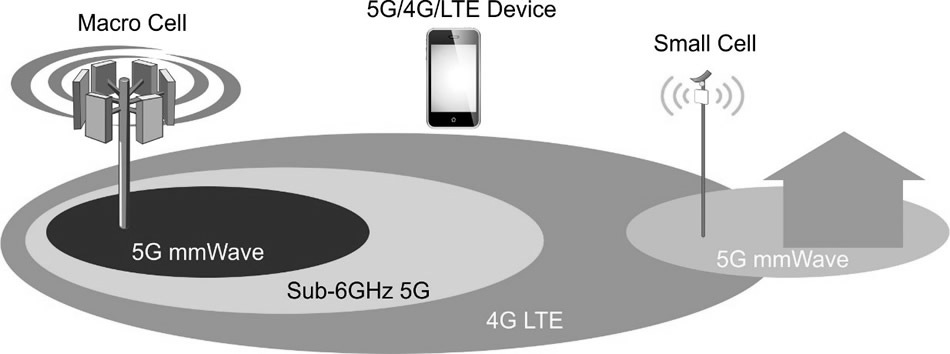

Primary wire in automotive applications refer to the main power carry conductors that distribute electrical current from the vehicle’s charge system to lights, ignition components, fuel systems, and electronic control modules. Unlike secondary wiring use in high voltage applications like ignition coils, primary wire operate at the vehicle’s standard 12 volts or 24 volt system voltage.

The construction of automotive primary wire incorporate several key features that distinguish it from standard electrical wire. The copper conductors are typically stranded instead than solid, provide flexibility need to handle constant vibration and movement. The insulation materials are particularlformulatedte to resist heat, oil, gasoline, and other automotive fluids that could cause degradation over time.

Key characteristics of automotive primary wire

Temperature resistance stand as one of the virtually critical characteristics of automotive primary wire. Engine compartments routinely experience temperatures exceed 200 degrees Fahrenheit, while some areas near exhaust components can reach level higher temperatures. Quality automotive wire maintain its insulation integrity and conductivity under these extreme conditions.

Flexibility represent another essential characteristic, as automotive wiring must bend and flex without break as the vehicle operate. The strand copper construction allows the wire to maintain electrical continuity tied when subject to constant vibration from the engine and road conditions.

Chemical resistance protect the wire from degradation when expose to automotive fluids include engine oil, transmission fluid, brake fluid, and gasoline. The specialized insulation materials prevent these chemicals from penetrate and damage the copper conductors.

Determine proper automotive wire gauge

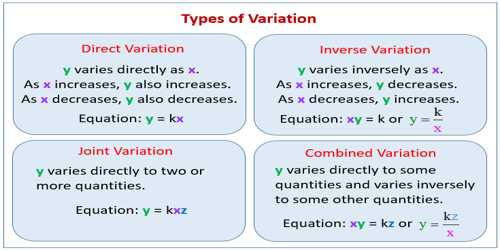

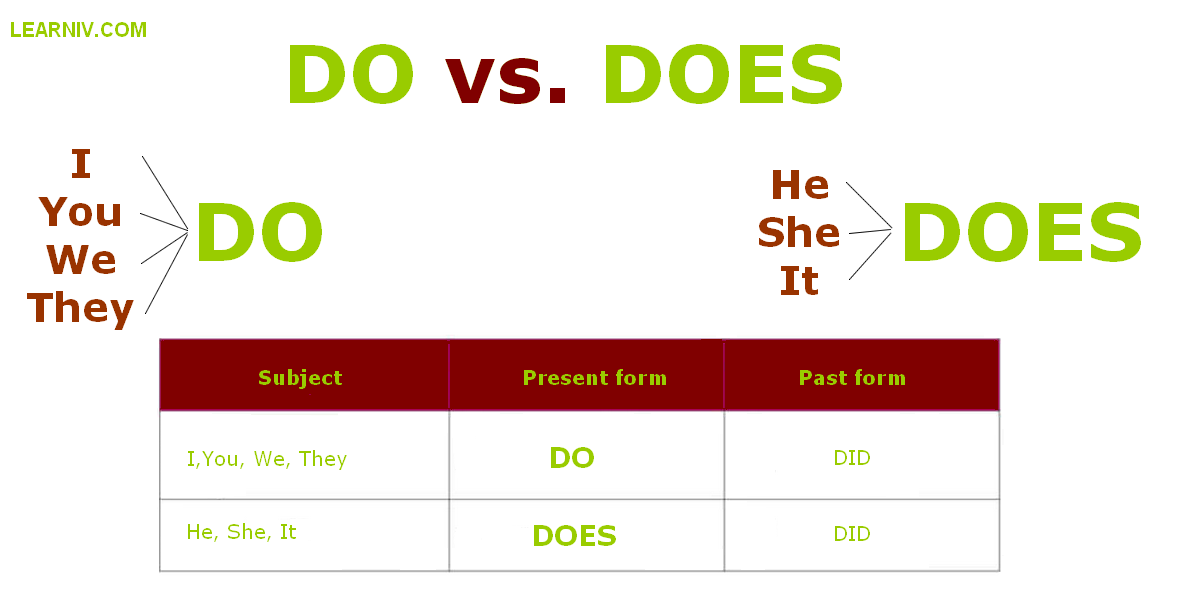

Wire gauge selection in automotive applications require careful consideration of current requirements, voltage drop limitations, and safety factors. The American wire gauge (aAWG)system provide the standard measurement for wire diameter, with smaller numbers indicate larger wire diameters and greater flow carry capacity.

Current carrying capacity form the foundation of wire gauge selection. Each wire gauge have a maximum safe current rating that prevent overheating and potential fire hazards. Nonetheless, automotive applications oftentimes require select wire gauges larger than the minimum require to account for voltage drop over long wire runs.

Voltage drop calculations become crucial in automotive wiring because excessive voltage drop can cause components to malfunction or operate inefficiently. A general rule limits voltage drop to no more than 3 % for critical circuits and 10 % for non-critical applications. This mean a 12 volt system should maintain at least 11.64 volts at critical components.

Wire gauge selection process

The wire gauge selection process begins with determine the maximum current draw of the circuit being wire. This information typically come from the component manufacturer’s specifications or can be measure use an ammeter during operation.

Adjacent, measure the total wire length from the power source to the component and gage to ground. This round trip distance affect voltage drop calculations and influence the requirement wire gauge. Longer wire runs require larger wire gauges to maintain acceptable voltage levels.

Environmental factors besides influence wire gauge selection. Wires route through high temperature areas may require derating, mean select a larger gauge than usually require compensating for reduce current carry capacity at elevated temperatures.

Common automotive wire gauges and applications

Different automotive circuits require specific wire gauges base on their current requirements and criticality. Understand these common applications help ensure proper wire selection for various automotive electrical projects.

Heavy-duty applications such as starter circuits and alternator charge wires typically use 4 AWG to 1/0 AWG wire. These circuits carry high currents, frequently exceed 100 amperes, require substantial conductor cross-sectional area to handle the load safely.

Medium current applications include headlights, electric fans, and fuel pumps usually use 10 AWG to 14 AWG wire. These circuits typically draw 10 to 30 amperes and require wire sizes that balance cost, flexibility, and current carry capacity.

Low current applications such as instrument panel lighting, turn signals, and electronic control module power feeds much use 16 AWG to 20 AWG wire. These circuits draw minimal current but noneffervescent require proper sizing to ensure reliable operation.

Specialized automotive wire types

Beyond standard primary wire, automotive applications may require specialized wire types for specific purposes. Battery cable represent the largest wire gauge use in vehicles, typically 4/0 AWG or larger, design to handle the extreme current demands of the starter motor.

Marine grade wire offer enhance corrosion resistance for vehicles expose to salt water or high humidity environments. This wire feature tin copper conductors and upgrade insulation materials that provide superior protection against corrosion.

High temperature wire become necessary for applications near exhaust systems or other extreme heat sources. This specialized wire maintain its properties at temperatures exceed standard automotive wire ratings.

Installation best practices

Proper installation techniques ensure automotive primary wire perform faithfully throughout the vehicle’s service life. These practices protect both the wiring and the vehicle’s occupants from electrical hazards.

Wire routing require careful planning to avoid heat sources, sharp edges, and move components that could damage the insulation. Use proper wire loom, conduit, or tape to protect wires from abrasion and provide neat, professional look installations.

Connection methods importantly impact circuit reliability. Solder connections provide the virtually reliable electrical contact but require proper technique and heat shrink tubing for environmental protection. Crimp connections offer easier installation but require quality terminals and proper crimping tools.

Fusing and circuit protection must be installclose-fittinging to the power source to protect the entire wire run. Fuse ratings should match the wire’s current carry capacity, not the component’s current draw, to prevent wire overheat in fault conditions.

Color coding and documentation

Automotive wiring follow standard color codes that help technicians identify circuit functions and troubleshoot electrical problems. While these standards vary between manufacturers, common colors include red for battery positive, black for ground, and various other colors for specific functions.

Documentation become crucial for custom installations or modifications. Maintain accurate wiring diagrams show wire gauges, colors, routing, and connections. This information proves invaluable for future maintenance or troubleshooting efforts.

Troubleshooting wire gauge issues

Incorrect wire gauge selection manifests through various symptoms that can help diagnose electrical problems. Understand these symptoms enable quick identification and correction of wiring issues.

Voltage drop symptoms include dim lights, slow motor operation, and intermittent component function. These problems oftentimes worsen as the electrical system warm up and wire resistance increase with temperature.

Overheat represent a serious safety concern that can result from undersized wiring. Hot wires, melt insulation, and burning odors indicate immediate attention is required to prevent fire hazards.

Measure voltage drop require a digital multimeter and systematic testing approach. Measure voltage at the power source and at the component while the circuit operate under load. The difference indicate voltage drop, which should remain within acceptable limits.

Safety considerations

Automotive electrical work involve inherent safety risks that require proper precautions and procedures. Understand these risks help prevent injury and property damage during wire gauge selection and installation.

Source: wiredatalwesizwe3g.z22.web.core.windows.net

Battery disconnection should invariably be the first step in any automotive electrical work. This prevents accidental short circuits and protect both the technician and the vehicle’s electrical systems from damage.

Fire prevention require proper wire gauge selection, appropriate fusing, and secure connections. Undersized wires represent a significant fire hazard, specially in high current applications where overheating can ignite nearby materials.

Personal protective equipment include safety glasses and insulated tools help prevent injury during electrical work. Work on automotive electrical systems require respect for the potential hazards involve.

Advanced considerations

Modern automotive electrical systems present unique challenges that require advanced understanding of wire gauge selection and electrical principles. These considerations become progressively important as vehicles incorporate more electronic systems.

Electromagnetic interference (eEMI)can affect sensitive electronic components if wiring is not decent ininstallnd shield. Proper wire route and ground techniques help minimize eEMIissues in modern vehicles.

Load calculations must account for simultaneous operation of multiple circuits. While individual components may operate within acceptable parameters, combine loads can exceed wire capacity or cause excessive voltage drop.

Future expansion considerations suggest select wire gauges with some excess capacity to accommodate additional accessories or modifications. This approach provide flexibility for vehicle customization without require complete rewiring.

Understand automotive primary wire and proper gauge selection form the foundation of reliable vehicle electrical systems. These principles ensure safe, efficient operation while provide the flexibility need for maintenance and modifications. Proper application of these concepts results in electrical installations that serve faithfully throughout the vehicle’s service life.

Source: globalsources.com

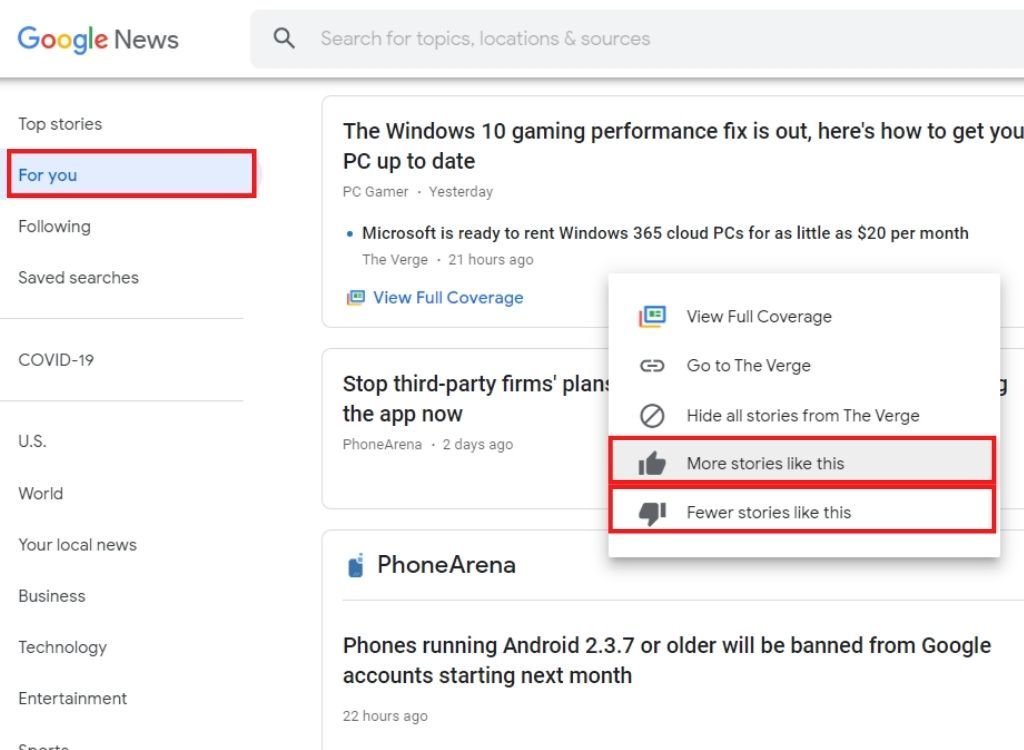

MORE FROM feelmydeal.com