Automotive Primer Drying Time: Complete Guide Before Sanding

Understand automotive primer drying times

Apply primer is a crucial step in any automotive painting project. Whether you’re restored a classic car, fix body damage, or refresh your vehicle’s appearance, know how long to let automotive primer dry before sanding can make the difference between professional look results and a disappointing finish.

Proper primer dry time ensure good adhesion, prevent future paint issues, and create the smooth foundation necessary for a flawless topcoat. This guide cover everything you need to know about primer dry times and the sand process.

Types of automotive primers and their drying times

Different primers serve different purposes and have varied dry times. Understand which typyourre use is essential for determining the correct wait period before sand.

Epoxy primer

Epoxy primer is known for its excellent adhesion and corrosion resistance properties.

- Dry to touch: 30 minutes to 1 hour

- Ready for sand: 12 24 hours (manufacturer recommendations vary )

- Full cure: Up to 7 days

Epoxy primers create an excellent foundation and are oftentimes use as the first layer in a multi-stage painting process. While you can sand after the recommend time, allow a full cure provide the best results, specially for projects require high quality finishes.

Urethane primer

Urethane primers offer good filling capabilities and sand easy.

- Dry to touch: 20 60 minutes

- Ready for sand: 2 4 hours

- Full cure: 24 hours

Urethane primers are popular for their versatility and comparatively quick dry times. They provide good adhesion and can be use over decent prepared bare metal, body filler, or exist finishes.

Lacquer primer

Lacquer primers dry rapidly but don’t offer the same durability as other options.

- Dry to touch: 15 30 minutes

- Ready for sand: 1 2 hours

- Full cure: 24 hours

The fast dry time of lacquer primers make them convenient for small repairs and projects with tight deadlines. Notwithstanding, they’re more susceptible to shrinkage over time and don’t provide the same level of protection as epoxy or urethane primers.

Self etch primer

Self etch primers are design specifically for bare metal surfaces.

- Dry to touch: 10 30 minutes

- Ready for sand: 1 2 hours (light sand sole )

- Full cure: 24 hours

These primers contain acids that etch into the metal surface, create excellent adhesion. They’re typically used as the first coat before apply a build primer orsurfacer.

High build primer surface

High build primers are design to fill minor imperfections.

- Dry to touch: 30 60 minutes

- Ready for sand: 3 8 hours

- Full cure: 24 hours

These thick primers build up promptly to fill scratches, sand scratches, and other minor surface flaws. They require more dry time but save effort in the long run by reduce the need for body filler.

Factors affecting primer drying time

The dry times list supra are general guidelines. Several factors can importantly impact how rapidly your primer dry and when it’s ready for sand:

Temperature

Temperature is may hap the virtually crucial factor affect primer dry time:

- Ideal temperature range: 70 80 ° f (21 27 ° c )

- Cold temperatures (below 60 ° f/15 ° c ) Importantly slow drying, potentially double or triple dry time

- Hot temperatures (above 90 ° f/32 ° c ) Can cause primer to dry excessively rapidly, lead to improper curing and potential adhesion issues

For best results, work in a temperature control environment whenever possible. If work outside or in an unheated garage, plan your project accord to weather forecasts.

Humidity

Moisture in the air affect solvent evaporation rates:

- High humidity (above 70 % ) Slows dry time and can cause haziness or poor adhesion

- Low humidity (below 30 % ) Can cause primer to dry excessively rapidly, potentially lead to poor flow and adhesion

- Ideal humidity range: 40 60 %

In humid conditions, consider use a dehumidifier in your work area. In really dry conditions, avoid apply primer during the hottest part of the day.

Air circulation

Proper airflow help solvents evaporate equally:

- Good air circulation promotes flush dry

- Stagnant air can trap solvents, extend dry time

- Excessive airflow (like direct fans )can cause dust contamination

A wellspring ventilate workspace with moderate air movement provide the best environment for primer dry.

Application thickness

The thickness of your primer coat dramatically affect dry time:

- Thin coats dry practically fasting than thick coats

- Multiple thin coats broadly perform better than one thick coat

- Overly thick applications can lead to solvent entrapment, result in extend drying times and potential curing problems

Invariably follow the manufacturer’s recommendations for application thickness. When in doubt, apply multiple thin coats quite than one heavy coat.

Primer formulation

Modern automotive primers come in various formulations:

- Water base primers: Broadly dry slowly than solvent base options

- Catalyzed primers: Dry accord to chemical reactions sooner than scarce solvent evaporation

- Reducers / thinners use: Fast, medium, or slow reducers affect dry time

Ever read the technical data sheet for your specific product to understand its unique dry characteristics.

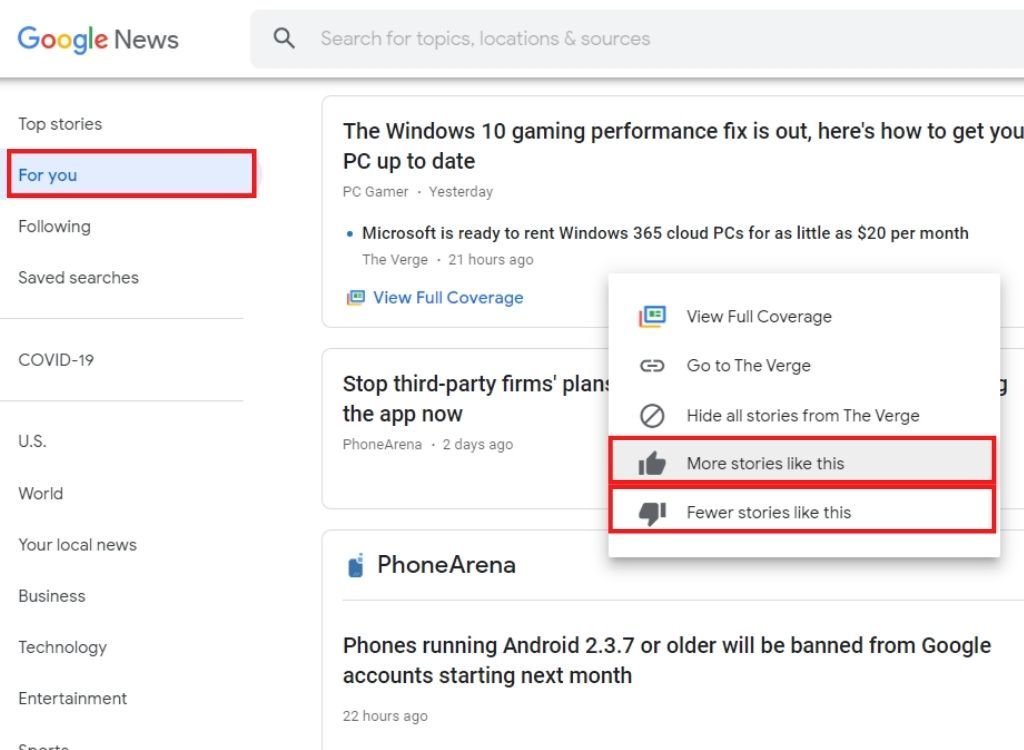

How to tell if primer is ready for sand

Sooner than rely exclusively on the clock, use these practical tests to determine if your primer is ready for sand:

The fingernail test

In an inconspicuous area:

Source: yardandgardenguru.com

- Press your fingernail hard into the primer

- If it leaves a clear impression, the primer is smooth excessively soft

- If your nail doesn’t leave a mark, it’s probably ready for sand

The sandpaper test

In a small test area:

- Gently sand with fine grit sandpaper (320 400 grit )

- If the primer gum up or roll rather of create a fine powder, it needs more dry time

- If it sands to a fine powder, it’s ready for full sand

Visual and touch assessment

Decently dry primer should:

- Have a uniform, matte appearance

- Feel dry and slimy rough to the touch

- Show no tacky or soft spots

If you notice any areas that look or feel different from the rest of the surface, allow more drying time.

Proper sanding techniques after primer has dry

East your primer has decent dry, follow these sand techniques for the best results:

Choose the right sandpaper

Select the appropriate grit base on your stage in the process:

- Initial sanding: 320 400 grit

- Final sand before paint: 600 800 grit

- For high build primers: You may start with 220 320 grit

Use quality sandpaper design for automotive applications. Wet or dry sandpaper work swell, depend on your preference and the primer type.

Wet vs. Dry sanding

Both methods have their advantages:

- Wet sanding: Reduce dust, prevent clog, and frequently provide a smoother finish

- Dry sanding: Easier to see progress, less mess, and better for certain primers

Check your primer manufacturer’s recommendations, as some primers perform wellspring with one method over the other.

Sand technique

Follow these best practices:

- Use a sanding block for flat surfaces to ensure evenness

- Sand in one direction, so perpendicular to it for uniform results

- Apply light to moderate pressure — let the sandpaper do the work

- Regularly check your progress by wipe away dust or water

- Pay special attention to edges and contours

Take your time during this stage — rush through sanding is a common cause of subpar paint jobs.

Guide to coat method

For professional results:

- Apply a light mist of contrast color (ofttimes black )over the dried primer

- As you’ll sand, this guide coat will disappear from high spots foremost

- Continue sand until the guide coat is altogether removed

- This method helps identify low spots and ensures level sand

Common mistakes to avoid

Yet experience divers make these mistakes when work with automotive primer:

Source: housetrick.com

Rush the process

May hap thewell-nighh common error is notallowedw sufficient dry time. Patience pay off — sand excessively shortly can:

- Clog sandpaper rapidly

- Create uneven surfaces

- Compromise adhesion of subsequent coats

- Lead to shrinkage issues previous

Ignore environmental conditions

Fail to account for temperature and humidity can lead to:

- Extended dry times in cold or humid conditions

- Improper cure in extreme conditions

- Surface defects from condensation or excessive heat

Apply overly thick coats

Thick primer application create multiple problems:

- Dramatically increase dry times

- Potential for solvent entrapment

- Greater risk of runs and sags

- Uneven cure of surface to substrate

Use incorrect sanding techniques

Poor sanding practices lead to disappointing results:

- Sand through the primer to the substrate

- Use excessively coarse sandpaper initially

- Apply excessive pressure

- Fail to sand equally across the entire surface

Accelerate primer drying time (when necessary )

While patience is ideal, sometimes you need to speed up the process. Here are some safe methods:

Heat lamps

Infrared heat lamps can safely accelerate dry:

- Position lamp 18 24 inches from the surface

- Keep heat moderate (around 120 140 ° f/49 60 ° c )

- Move lamps regularly to prevent hotspots

- Monitor temperature with an infrared thermometer

Paint booth heating

If available, a heated paint booth provide ideal conditions:

- Control temperature around 140 ° f/60 ° c

- Filter air to prevent contamination

- Yet heat across the entire vehicle

Accelerators and fasting dry products

Chemical options include:

- Fasting dry reducers / thinners design for your specific primer

- Accelerator additives (use purely accord to manufacturer specifications )

- Choose inherently fasting dry primer formulations

Invariably follow product guidelines — improper use of accelerators can compromise finish quality.

Professional tips for perfect results

These expert insights can elevate your automotive priming and sand results:

Plan accord to conditions

Professionals adapt their approach base on the environment:

- In cold weather, use heat lamps or portable heaters to maintain temperature

- In humid conditions, schedule work during the driest part of the day

- Consider use a different reducer / thinner base on conditions

Test before proceeding

Verify readiness before full sanding:

- Constantly perform the fingernail and sandpaper tests

- Test in multiple areas, as dry can be uneven

- When in doubt, wait foresight — patience is less costly than redo work

Document your process

Keep records for future reference:

- Note environmental conditions, products use, and dry times

- Take photos at different stages

- Record what work good and what don’t

This documentation help refine your process for future projects.

Conclusion

The question of how long to let automotive primer dry before sanding doesn’t have a one size fit all answer. Dry times vary base on primer type, environmental conditions, application thickness, and other factors.

Mostly, you should wait at least:

- 1 2 hours for lacquer primers

- 2 4 hours for urethane primers

- 12 24 hours for epoxy primers

Yet, these are minimum times — allow primers to full cure most invariably produce superior results. When possible, give epoxy primers a full 24 hours and other types at least all night before sand.

Remember that proper primer application and sanding create the foundation for your paint job. Take the time to do these steps aright will pay dividends in the final appearance and durability of your automotive finish.

By understand the factors that will affect will dry time and will use the testing methods will describe supra, you will develop the judgment will need to will achieve professional quality results in your automotive refinishing projects.

MORE FROM feelmydeal.com