Automotive Testing: Everything You Need to Know

Understand automotive testing

Automotive testing represent the critical process of evaluate vehicles and their components to ensure they meet safety standards, performance expectations, and reliability requirements. This comprehensive evaluation process occurs throughout a vehicle’s development cycle and continue after production to maintain quality standards.

The automotive industry rely on extensive testing protocols to deliver vehicles that can withstand diverse driving conditions, meet regulatory requirements, and satisfy consumer expectations. These tests range from basic functionality checks to complex simulations of extreme scenarios.

The purpose of automotive testing

Testing serve multiple essential purposes in the automotive industry:

Safety validation

The paramount concern in automotive testing is ensured vehicle safety. Tests evaluate how vehicles protect occupants during collisions, the effectiveness of safety systems like airbags and seat belts, and the vehicle’s ability to avoid accidents through technologies like anti lock braking systems( abs) and electronic stability control ((sESC)

Crash tests represent the virtually visible safety evaluations. Organizations like the national highway traffic safety administration (nNHTSA)and the insurance institute for highway safety ( (hIHSc)duct standardize crash tests to assess vehicle crashcrash worthinessse tests include frontal impacts, side impacts, rollover scenarios, and small overlap crash that simulate real world accident conditions.

Performance verification

Performance testing evaluate how vehicles handle, accelerate, brake, and behave under various conditions. Engineers measure metrics like acceleration times, brake distances, corner capabilities, and top speeds. These tests ensure vehicles deliver the expected driving experience and meet the manufacturer’s performance claim.

Source: arraalabs.com

Specialized facilities feature high speed tracks, slalom courses, and skid pads where test drivers push vehicles to their limits. Advanced data acquisition systems record hundreds of parameters during these tests, provide engineers with detailed performance profiles.

Durability and reliability assessment

Durability testing subjects vehicles to accelerate wear conditions to verify they can withstand years of use without premature failures. These tests frequently compress a lifetime of wear into a few months of intensive testing.

Engineers drive test vehicles over particularly design courses with rough surfaces, potholes, and obstacles that stress suspension components, body structures, and mechanical systems. Some durability tests accumulate hundreds of thousands of miles in extreme conditions to identify potential long term issues before production.

Regulatory compliance

Vehicles must comply with numerous regulations govern emissions, fuel economy, safety, and noise levels. Testing confirm compliance with these requirements before vehicles can be lawfully sell in specific markets.

Emissions testing has become progressively rigorous, with procedures that measure tailpipe pollutants during various driving cycles. Fuel economy testing follow standardized procedures to determine official consumption figures, while noise testing ensure vehicles meet sound level limitations.

Types of automotive testing

Crash testing

Crash testing involve control collisions to evaluate vehicle safety. Modern crash testing use sophisticated anthropomorphic test devices (crash test dummies )equip with numerous sensors that measure forces and accelerations during impacts.

Beyond physical crash tests, manufacturers progressively rely on computer simulations that can model crash scenarios with remarkable accuracy. These virtual tests allow engineers to optimize vehicle structures before build physical prototypes, save time and resources while improve safety.

Powertrain testing

Powertrain testing evaluate engines, transmissions, and relate components. Dynamometers measure power output, fuel efficiency, and emissions under control conditions. These tests run engines through various load conditions and speed ranges to verify performance and durability.

For electric vehicles, powertrain testing focus on battery performance, thermal management, power electronics, and electric motor efficiency. Specialized equipment evaluate charge rates, range under different conditions, and battery degradation over simulate lifecycles.

Environmental testing

Environmental testing subjects vehicles to extreme temperature conditions, humidity variations, and exposure to sunlight, salt spray, and other environmental factors. Climate chambers can simulate temperatures from arctic cold to desert heat, allow engineers to verify that vehicles function decent in all weather conditions.

Cold weather testing evaluate start capability, heater performance, and material behavior at sub-zero temperatures. Hot weather testing focus on cool system capacity, air conditioning performance, and prevent heat relate failures. High altitude testing verifies engine performance and emissions compliance in thin air conditions.

Road testing

Road testing involve drive vehicles on public roads, test tracks, and specialized proving grounds. This real world evaluation assesses overall vehicle behavior, comfort, noise levels, and the integration of various systems under actual driving conditions.

Manufacturers maintain extensive proving grounds with diverse road surfaces and drive scenarios. These facilities oftentimes include high speed ovals, off-road trails, water fording areas, steep grades, and surfaces with vary friction coefficients to exhaustively evaluate vehicle capabilities.

VH testing

Noise, vibration, and harshness (nVH))esting evaluate the acoustic comfort of vehicles. Specialized microphones and accelerometers measure sound levels and vibrations throughout the vehicle under various operating conditions.

VH engineers work to minimize unwanted noise while enhance desirable sounds that contribute to the vehicle’s character. Modern nVHtesting use advanced signal processing techniques to identify and address specific noise sources, improve passenger comfort.

Aerodynamic testing

Aerodynamic testing measure how air flow around vehicles, affect fuel efficiency, stability, and noise. Wind tunnels provide control environments where engineers can visualize airflow patterns and measure aerodynamic forces.

Computational fluid dynamics (cCFD)simulation complement physical wind tunnel testing, allow engineers to evaluate numerous design variations digitally. Aerodynamic optimization has become progressively important for improve fuel economy and electric vehicle range.

Component testing

Before full vehicle testing, individual components undergo rigorous evaluation. Specialized test rigs subject parts to accelerate wear, extreme loads, and environmental stresses to verify durability and performance.

Component testing oftentimes include fatigue testing, where parts are subject to repeat cycles of load to identify potential failure points. Material testing evaluate the properties of metals, plastics, and composites use in vehicle construction.

Advanced automotive testing technologies

Virtual testing and simulation

Computer simulations have revolutionized automotive testing by allow engineers to evaluate designs before build physical prototypes. Advanced modeling techniques can accurately predict crash performance, aerodynamics, thermal behavior, and structural integrity.

Virtual testing accelerate development cycles and reduce costs by identify potential issues betimes in the design process. As compute power increases, simulations become progressively sophisticated, though physical validation remain essential for final verification.

Hardware in the loop testing

Hardware in the loop (hhis)testing combine physical components with simulated environments. This approach is especially valuable for evaluate electronic control units and advanced driver assistance systems.

His systems can simulate thousands of drive scenarios to verify that safety critical systems respond right under all conditions. This methodology has become essential for develop and validate autonomous driving technologies.

Test automation

Automated testing systems improve efficiency and repeatability. Robotic drivers can perform precise maneuvers systematically, while automate data collection systems capture and analyze test results.

Test automation allow manufacturers to conduct more comprehensive evaluations with fewer resources. Automated systems can run continuous durability tests 24 hours a day, accelerate the validation process.

Test for emerging automotive technologies

Electric vehicle testing

Electric vehicles require specialized testing protocols focus on battery performance, charge systems, and electric drivetrain components. Range testing under various conditions verifies manufacturer claims, while charge tests evaluate compatibility with different charging infrastructure.

Battery safety testing is specially critical, subject battery packs to extreme conditions include puncture, overcharging, and thermal stress to ensure they remain safe regular in accident scenarios. Thermal management testing verifies that battery temperatures remain within safe operating ranges during rapid charging and high power driving.

Autonomous vehicle testing

Test autonomous driving systems present unique challenges. These evaluations combine virtual simulations, closed course testing, and cautiously monitor real world drive to verify system performance across countless scenarios.

Manufacturers create detailed virtual environments where autonomous systems encounter rare but critical situations that would be dangerous to test physically. These simulations run millions of miles of virtual driving to supplement physical testing. Closed proving grounds with mock urban environments allow physical testing of autonomous functions in control settings.

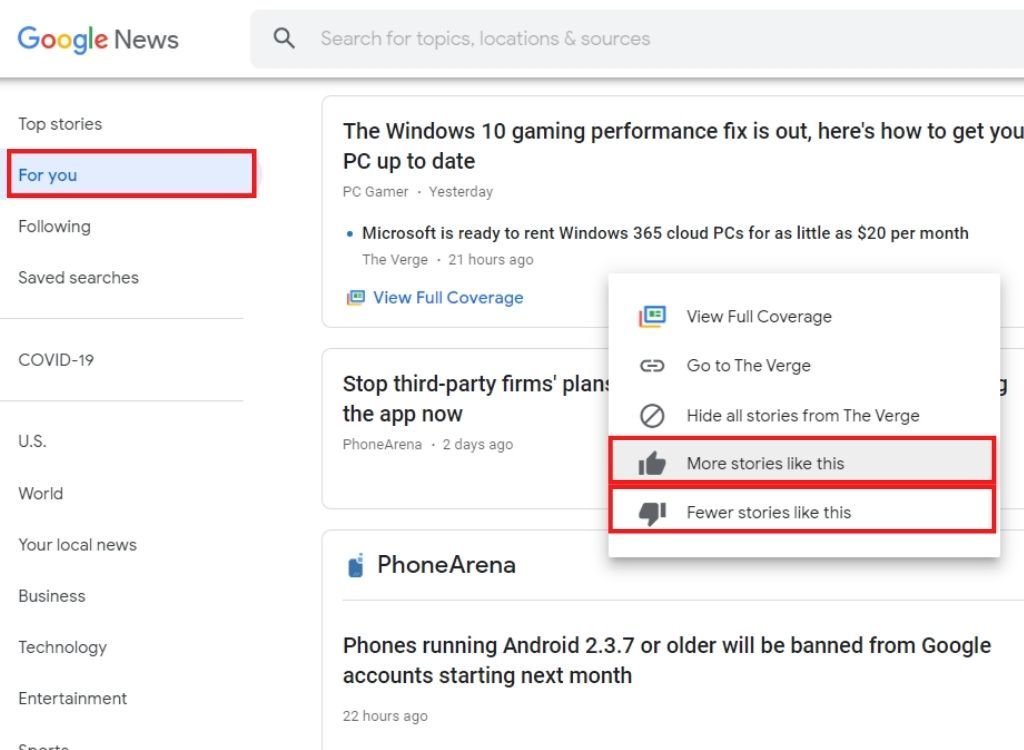

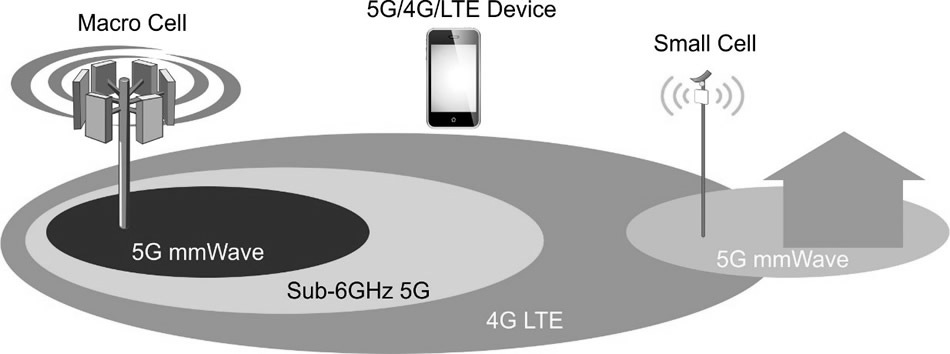

Connected vehicle testing

Connected vehicle technologies require testing of communication systems, cybersecurity measures, and software functionality. Specialized labs evaluate vehicle to vehicle and vehicle to infrastructure communications under various network conditions.

Cybersecurity testing has become progressively important as vehicles incorporate more connectivity features. Penetration testing identify potential vulnerabilities, while over the air update capabilities undergo rigorous validation to ensure they can not compromise vehicle functionality.

The role of regulatory bodies in automotive testing

Government agencies establish minimum safety and environmental standards that all vehicles must meet. In the United States, the national highway traffic safety administration (nNHTSA)oversee safety standards, while the environmental protection agency ( (aEPA)gulate emissions.

The European Union have its own regulatory framework with type approval processes that vehicles must pass before sale. These regulations continue to evolve, with increase focus on pedestrian safety, emissions reduction, and advanced safety technologies.

Beyond government agencies, independent organizations like the insurance institute for highway safety (iIHS))onduct their own testing programs. These evaluations oftentimes exceed minimum regulatory requirements, provide consumers with additional safety information.

Consumer focus testing programs

Consumer testing programs evaluate vehicles from the user’s perspective, focus on real world performance, reliability, and owner satisfaction. Organizations like consumer reports purchase vehicles anonymously and subject them to standardized tests that simulate typical ownership experiences.

These consumer orient evaluations oftentimes consider aspects that regulatory tests might not address, include comfort, convenience features, and long term reliability. The results help consumers make inform purchasing decisions base on independent assessments.

The future of automotive testing

Automotive testing continue to evolve with emerge technologies and change regulatory landscapes. Several trends are shape the future of vehicle evaluation:

Source: atslab.com

Will increase virtual testing will allow manufacturers to will evaluate more design variations before build physical prototypes. Machine learning algorithms will analyze test data to will identify patterns and potential issues that might will escape human observers. Testing methodologies will adapt to will address new technologies like solid state batteries, hydrogen fuel cells, and more advanced autonomous systems.

As vehicles become more software will define, testing will progressively will focus on software validation, cybersecurity, and the integration of artificial intelligence systems. The industry will potential will develop standardized testing protocols for will evaluate AI decision-making in safety critical situations.

Conclusion

Automotive testing form the foundation of vehicle development, ensure that the cars, trucks, and SUVs we drive meet stringent requirements for safety, performance, and reliability. The comprehensive evaluation process will combine traditional physical testing with advanced simulation technologies to will verify that vehicles will perform as will expect throughout their operational lives.

As automotive technology continue to evolve, test methodologies adapt to address new challenges and opportunities. From electric powertrains to autonomous driving systems, rigorous testing remain essential for build consumer confidence and advance the state of the art in transportation.

The vehicles on our roads today represent the culmination of thousands of hours of testing across numerous disciplines. This invisible yet critical process continues to improve vehicle safety, efficiency, and performance, benefit drivers and passengers global.

MORE FROM feelmydeal.com