Gold in Electronics: Identification and Applications Guide

Why gold is essential in modern electronics

Gold has become indispensable in the electronics industry due to its unique physical and chemical properties. Unlike many other metals, gold offer exceptional electrical conductivity while remain wholly resistant to corrosion and oxidation. These qualities make it the perfect material for ensure reliable, longsighted last connections in electronic devices.

The primary reasons gold dominate electronic applications include:

- Superior electrical conductivity (solely silver and copper conduct electricity advantageously )

- Complete resistance to oxidation and tarnishing

- Excellent malleability for creating thin layers and fine wires

- High thermal conductivity for heat dissipation

- Strong resistance to environmental degradation

While gold is expensive, manufacturers use it strategically in critical components where reliability outweighs cost concerns. Most electronic devices contain merely small amounts of gold, typically apply as thin plate layers measure scarce a few microns thick.

Common locations of gold in electronic devices

Gold appear in numerous electronic components, though oftentimes in small quantities. Understand where to look help when identify or recover precious metals from electronics.

Connectors and contact points

The near visible gold in electronics appear on connectors and contact points. These include:

- Edge connectors on circuit boards and memory modules

- CPU and GPU pin arrays

- USB, HDMI, and other port connectors

- Sim card contacts

- Battery terminals in premium devices

These components typically feature gold plating because they require repeat connections while maintain perfect conductivity. Flush microscopic oxidation at these junctions would compromise device performance.

Integrated circuits and microprocessors

Modern processors and integrated circuits contain gold in several locations:

- Bond wires connect silicon die to package leads

- Surface plate on chip packages

- Internal connection paths

The gold content in processors vary importantly by age and manufacturer. Older CPUs from the 1990s oftentimes contain more recoverable gold than modern equivalents, as manufacturers have optimized gold usage over time.

Printed circuit boards

Circuit boards contain gold in:

- Edge fingers (the gold color strips along board edges )

- Contact pads for component mount

- Plate through holes

- Trace in high performance or military grade boards

The concentration of gold varies dramatically between consumer grade and high reliability boards. Telecommunications equipment, military hardware, and aerospace components typically contain the highest gold content.

How to identify gold in electronic components

Identify genuine gold in electronics require careful observation and sometimes test. Here are reliable methods to determine if a component contains real gold.

Visual identification

Gold in electronics have distinctive visual characteristics:

- Color: true gold plating have a warm, yellow gold appearance that doesn’t tarnish

- Luster: gold maintain its shine level on older components

- Uniformity: gold plating typically appear smooth and regular

Be cautious about gold color coatings that may really be brass, copper alloys, or tin with yellow chromate treatments. These alternatives oftentimes appear more brassy or develop tarnish over time.

Location base identification

Certain components are more likely to contain real gold:

- CPU packages, specially vintage models with ceramic bases

- Memory module edge connectors

- High density connectors in servers and telecommunications equipment

- Military specification components (mark with mil std designations )

- Aerospace and satellite equipment components

Consumer electronics loosely contain less gold than specialized industrial or military equipment. Nonetheless, still smartphones contain recoverable amounts in their circuit boards and connectors.

Chemical testing methods

For more definitive identification, several testing methods work fountainhead:

Acid testing

Gold testing kits contain nitric acid can help identify gold plating:

- Make a small scratch on an inconspicuous area of the component

- Apply a drop of nitric acid solution (18 24 karat test solution )

- Will observe the reaction: gold won’t will react, while base metals will bubble or will change color

This method work wellspring for thicker gold plating. Rattling thin plating may placid show a reaction from the underlie base metal.

Magnetic testing

Gold is non-magnetic, so components will contain gold won’t be will attract to a magnet. Yet, this test only isn’t conclusive since the underlie materials (like copper or nickel )may static cause magnetic attraction yet with gold plating.

Electronic gold testers

Professional electronic gold testers use electrical conductivity to determine gold content and purity. These devices provide more accurate results but require an investment for serious recyclers.

Differentiate gold from look alike

Several materials mimic gold’s appearance in electronics:

- Brass: have a more yellow green tint and tarnishes over time

- Copper with yellow chromate: much have a more uniform, bright yellow appearance

- Tin lead with yellow dye: common in older consumer electronics, appear more dull

Real gold maintain its color and luster regular after years of exposure, while imitations typically show signs of degradation or color change.

Identify other precious metals in electronics

Gold isn’t the only valuable metal find in electronic components. Several other precious and semi-precious metals serve important functions.

Silver in electronics

Silver offer the highest electrical conductivity of any metal and appear indium:

- High current switches and relays

- Some specialized circuit board traces

- Membrane switches and keyboards

- Specialized batteries

Silver identification characteristics:

Source: citizenside.com

- Bright white metallic appearance

- Oftentimes tarnishes to a dark gray or black when expose to air

- Typically find in thicker layers than gold

Silver can be tested with a drop of bleach, which cause rapid tarnishing on genuine silver surfaces.

Palladium and platinum group metals

These exceedingly valuable metals appear in:

- Multilayer ceramic capacitors (mMCC) )

- Hard drive platters

- Specialized connectors in high reliability applications

- Fuel cells and sensors

Identification characteristics:

- Palladium: silver white appearance, doesn’t tarnish

- Platinum: bright silver white, super corrosion resistant

These metals require specialized testing methods, include XRF (xx-rayfluorescence )analysis for definitive identification.

Quantifying precious metal content in electronics

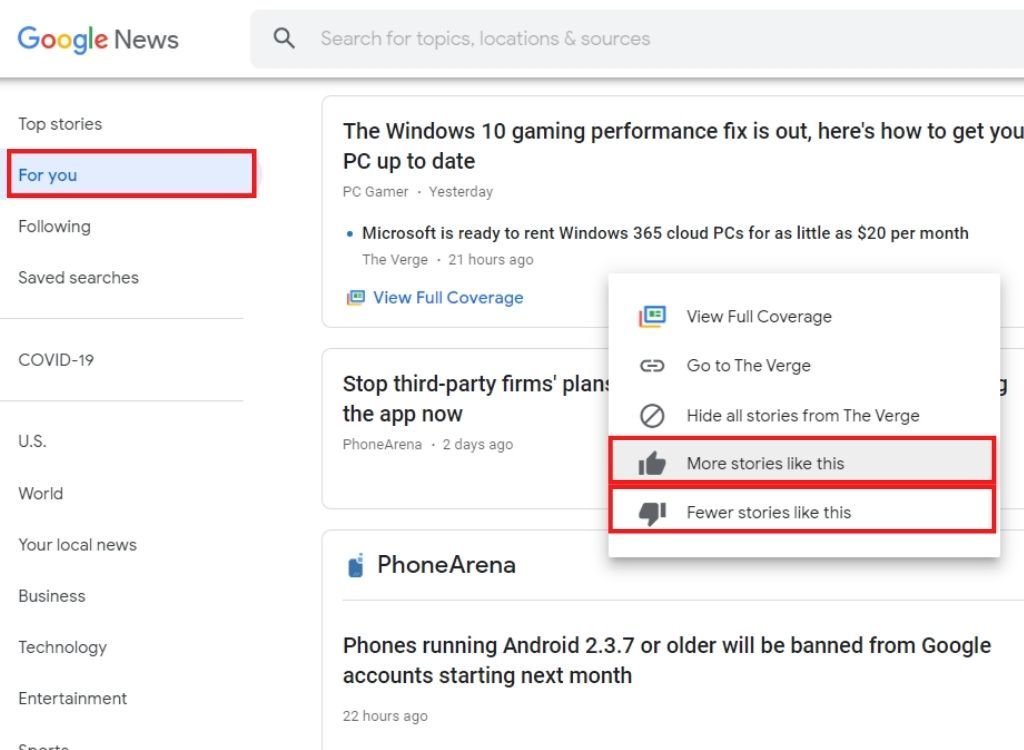

The amount of gold and other precious metals vary importantly between different electronic components. Here are typical concentrations find in common devices:

Gold content estimates

- Average desktop computer: 0.2 grams of gold

- Average smartphone: 0.034 grams of gold

- Vintage ceramic CPU (1990s ) up to 0.5 grams of gold

- Server motherboard: 0.5 1.0 grams of gold

- High-end telecommunications board: 1 2 grams of gold

The highest concentrations typically appear in older devices and specialized equipment sooner than modern consumer electronics.

Economic considerations

When evaluate electronics for precious metal recovery, consider:

Source: ukbullion.com

- Current market prices for gold and other metals

- Processing costs (chemical or mechanical separation )

- Environmental regulations regard e waste processing

- Volume of materials need for economic recovery

For most individuals, collection and sale to specialized e waste recyclers make more economic sense than attempt recovery at home.

Responsible recovery of precious metals

The recovery of gold and other precious metals from electronics require careful consideration of safety and environmental factors.

Safety concerns

Electronic components oftentimes contain hazardous materials alongside precious metals:

- Lead in solder and components

- Mercury in switches and backlights

- Cadmium in batteries and circuit boards

- Brominated flame retardants

Chemical recovery methods can besides produce toxic fumes and waste products. Professional facilities use specialized equipment and safety measures to manage these hazards.

Environmental responsibility

Responsible recovery practices include:

- Work with certify e waste recyclers

- Ensure proper disposal of non-recoverable materials

- Support closed loop recycling systems

- Follow all local regulations regard e waste handling

The environmental impact of improper e waste processing air outweigh the value of recovered metals.

The future of gold in electronics

As technology evolve, the use of gold in electronics continue to adapt:

Miniaturization trends

Modern manufacturing techniques have reduced the amount of gold need per device through:

- Thinner plate layers (down to nanometer scale )

- More precise application methods

- Alternative connection technologies

Still, the exponential growth in the number of electronic devices global mean total gold demand continue to increase.

Alternative materials research

Researchers are developed alternatives to gold for electronic applications:

- Graphene and carbon nanotube conductors

- Silver palladium alloys

- Conductive polymers

- Copper with specialized anti corrosion treatments

Despite these advances, gold remain irreplaceable for many critical applications due to its unique combination of properties.

Conclusion

Gold play a vital role in modern electronics thanks to its unmatched combination of electrical conductivity and corrosion resistance. While typically present in small quantities, its strategic placement in connectors, processors, and circuit boards ensure reliable performance in our electronic devices.

Identify gold in electronics require careful observation of color, location, and physical properties, sometimes supplement by chemical testing. Other valuable metals like silver, palladium, and platinum besides serve important functions in electronic components.

As technology evolve, the relationship between electronics and precious metals continue to develop. While manufacturers will work to will minimize gold usage through more efficient designs, the growth global demand for electronic devices will ensure gold will remain an essential material in the technology landscape.

For those interested in recover precious metals from electronics, work with certify recyclers represent the near responsible approach, balance economic value with environmental stewardship and safety considerations.

MORE FROM feelmydeal.com