Plasma Technology: Commercial Applications Transforming Modern Industries

Understand plasma: the fourth state of matter

When we think about states of matter, solids, liquids, and gases typically come to mind. Still, plasma — much call the fourth state of matter — play a crucial role in numerous commercial technologies that shape our modern world. Plasma forms when gases are energized to the point where electrons separate from atoms, create a mixture of charge particles that exhibit unique properties.

Unlike conventional gases, plasmas conduct electricity, respond to electromagnetic fields, and can reach highly high temperatures. These characteristics make them invaluable across diverse industries from electronics to medicine.

Display technology: bring images to life

One of the virtually recognizable commercial applications of plasma technology is in display screens. Plasma display panels (pPDP))evolutionize the television industry by offer larger screen sizes with superior picture quality compare to traditional cathode ray tube ( c( CRT)evisions.

How plasma displays work

Plasma displays operate by contain tiny cells fill with noble gases (typically xenon and neon )between two glass panels. When electricity flow through these cells, the gas become ionized, transform into plasma that emit ultraviolet light. This ultraviolet light so strike phosphors cocoatshe inside of the cells, cause them to emit visible light in various colors.

While OLED and LCD technologies have mostly supplanted plasma displays in recent years, plasmTVsvs wergroundbreakerke for their time, offer superior black levels, wider view angles, and better performance in display fasting move images.

Semiconductor manufacturing: the foundation of electronics

Peradventure the virtually economically significant application of plasma technology lie in semiconductor manufacturing — the backbone of all modern electronics from smartphones to supercomputers.

Source: phys.org

Plasma etch

Plasma etch is a critical process in fabricate integrate circuits and microchips. This technique use plasma to remove material selectively from a substrate (typically silicon wafers ) By exactly control the plasma’s properties, manufacturers can create implausibly intricate patterns with features measure precisely nanometers in width.

The process works by generate plasma from gases like sulfur hexafluoride or tetrafluoromethane. The plasma create reactive species that chemically react with the substrate surface, remove material with extraordinary precision that would be impossible with conventional chemical etch.

Plasma enhance chemical vapor deposition (pPECVD)

Another crucial semiconductor manufacturing technique is PECVD, which use plasma to facilitate the deposition of thin films onto substrates. The plasma break down precursor gases into reactive species that so form solid materials on the substrate surface.

This process enable the creation of high quality thin films for various electronic components, include transistors, capacitors, and resistors. PECVD operate at lower temperatures than traditional chemical vapor deposition, allow for more versatile manufacturing processes.

Lighting: illuminate our world

Plasma base lighting technologies have been illuminated commercial and residential spaces for decades.

Fluorescent lamps

Fluorescent tubes, normally find in office buildings, retail stores, and industrial facilities, utilize plasma to generate light. These lamps contain mercury vapor that, when energize by an electric current, form a plasma that emit ultraviolet radiation. This radiation so excite a phosphor coat on the inside of the tube, which convert the ultraviolet light to visible light.

High intensity discharge (hid )lamps

Hid lamps, include metal halide, high pressure sodium, and mercury vapor lamps, besides employ plasma technology. These lamps create an arc of plasma between two electrodes in a seal tube contain metal salts and noble gases. The intense light produce make them ideal for street lighting, sports stadiums, and other applications require powerful illumination over large areas.

Plasma cutting and welding: revolutionize manufacturing

In industrial manufacturing, plasma technology has transformed how materials are cut and join unitedly.

Plasma cutting

Plasma cutting use a high velocity jet of ionized gas (plasma )to cut through electrically conductive materials like steel, aluminum, brass, and copper. The process begin with compress gas ( (ttimes oxygen, nitrogen, argon, or air ) )ow through a narrow nozzle. A powerful electric arc forms between an electrode inside the torch and the workpiece, turn the gas into plasma.

This plasma stream, which can reach temperatures of up to 30,000 ° f (16,649 ° c ) melt the metal and blow the molten material off to create a clean cut. Plasma cutting offer several advantages over traditional methods:

- Ability to cut thick materials (up to 6 inches for some systems )

- Higher cutting speeds than OXY fuel cutting

- Precision cut with minimal material distortion

- Capability to cut stack materials

Plasma arc welding

Plasma arc weld use a similar principle but for join kinda than cut materials. A constrict plasma arc provide a concentrated heat source that create strong, high quality welds. This technique is peculiarly valuable for precision welding applications in aerospace, automotive, and medical device manufacturing.

Surface modification and coatings

Plasma technology excels at modify material surfaces to enhance their properties or apply specialized coatings.

Plasma surface treatment

Low temperature plasma treatments can alter the surface properties of materials without affect their bulk characteristics. These treatments can:

- Improve adhesion for bonding, printing, or coat

- Increase testability

- Enhance biocompatibility for medical devices

- Create antimicrobial surfaces

- Improve corrosion resistance

Industries range from automotive to packaging use plasma surface treatments to solve challenge material interface problems.

Source: helloranker.com

Plasma spray coatings

Plasma spray technology apply protective or functional coatings to various substrates. The process involve inject powder material into a plasma jet, which melt the particles and propel them onto the target surface. Upon impact, the particles flatten and solidify, form a durable coating.

This technique create thermal barrier coatings for jet engine components, wear resistant coatings for industrial equipment, and biocompatible coatings for medical implants.

Waste treatment and environmental applications

Plasma technology offer powerful solutions for environmental challenges, peculiarly in waste management.

Plasma gamification

Plasma gamification use super high temperature plasma (up to 10,000 ° f or 5,538 ° c )to convert organic waste materials into synthesis gas ( (nsongsa) an inert vitrified slag. Unlike incineration, plasma gasifgamificationk down waste at the molecular level through thermal decomposition.

The result songs — mainly hydrogen and carbon monoxide — can be uusedas a fuel for electricity generation or convert into liquid fuels. Meantime, inorganic components are transformed into a glassynon-leachablele slag useful in construction materials.

This technology can process municipal solid waste, hazardous waste, medical waste, and flush challenging materials like asbestos with minimal environmental impact.

Plasma in healthcare and medicine

The medical field progressively leverage plasma technology for various therapeutic and sterilization applications.

Cold atmospheric plasma (cap )therapy

Cap therapy use non-thermal plasma generate at atmospheric pressure to treat various medical conditions. Unlike thermal plasmas use in industrial applications, cold plasma operate at near room temperature, make it safe for direct contact with live tissue.

Medical applications include:

- Wound healing acceleration

- Sterilization of heat sensitive medical equipment

- Dental treatments for cavity prevention and periodontal disease

- Cancer therapy (selectively target cancer cells )

- Blood coagulation

Plasma sterilization

Plasma sterilization systems use hydrogen peroxide or other gas plasmas to eliminate pathogens on medical instruments and devices. This low temperature sterilization method efficaciously destroy microorganisms without damage heat sensitive equipment.

Aerospace and space applications

Plasma technology play a crucial role in space exploration and satellite systems.

Plasma thrusters

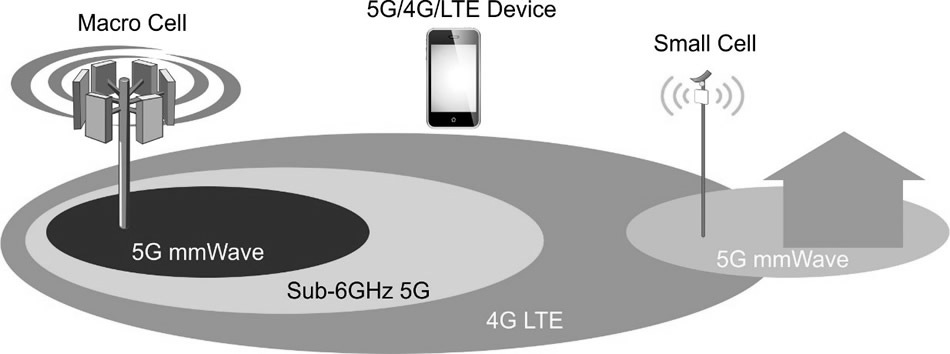

Electric propulsion systems, specially hall effect thrusters and ion engines, use plasma to generate thrust for spacecraft. These engines ionize propellant (typically xenon )and accelerate the result plasma use electric fields. While produce less thrust than chemical rockets, plasma thrusters are extremely efficient and can operate incessantly for years, make them ideal for satellite station keeping and deep space missions.

Plasma shielding

Research continue into use plasma as a shield against radiation and high speed particles in space, potentially protect astronauts during long duration missions.

Analytical instruments and research tools

Plasma base analytical instruments provide powerful tools for scientific research and quality control.

Inductively couple plasma mass spectrometry (iICPms )

ICP ms instruments use high temperature plasma to ionize samples, allow for highly sensitive detection and quantification of elements. This technology can detect elements at concentrations arsenic low as one part per trillion, make it invaluable for environmental monitoring, geological analysis, semiconductor quality control, and forensic investigations.

Plasma chromatography

Besides know as ion mobility spectrometry, plasma chromatography use plasma ionization to separate and identify chemical compounds. This technique find applications in explosive detection at airports, drug testing, and chemical warfare agent detection.

Future directions in commercial plasma technology

As research advances, several emerge plasma technologies show promise for commercial applications:

- Plasma agriculture: use plasma activate water and direct plasma treatment to enhance seed germination, plant growth, and pest control

- Plasma catalysis: combine plasma with catalysts to enable chemical reactions under milder conditions with improved selectivity

- Plasma fusion energy: develop commercial fusion reactors that use plasma to generate clean, abundant energy

- Plasma electronics: create novel electronic devices base on plasma properties instead than solid state physics

Conclusion

From the displays that deliver our entertainment to the processes that fabricate our electronic devices, plasma technology has become an integral part of modern commercial infrastructure. Its unique properties — conductivity, responsiveness to electromagnetic fields, and ability to reach extreme temperatures — enable applications that would be impossible with conventional materials.

As research will continue and new applications will emerge, plasma technology will potential will play a progressively important role in will address complex challenges across industries. The versatility of plasma make it a powerful tool for innovation, drive advancements in electronics, manufacturing, medicine, environmental remediation, and beyond.

MORE FROM feelmydeal.com